|

|

Research Projects

Research Projects

Multiscale Simulation of Nano- and Poly-Crystalline Materialsi-Science and Engineering of Interface Materials

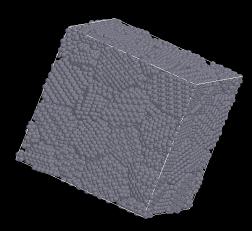

" On the left is the nanocrystalline sample

generated by a new algorithm developed in the computational materials

science group. The "digital" sample has 200 grains with average grain

size of 6 nanometers. This algorithm captures the features of

poly-crystalline materials with correct grain boundary structure, size,

and other topological characteristics. We are currently carrying out

large scale molecular dynamics simulation and finite element modeling

to investigate thermodynamic, transport, magnetic and mechanical properties of

nanocrystalline materials."

" On the left is the nanocrystalline sample

generated by a new algorithm developed in the computational materials

science group. The "digital" sample has 200 grains with average grain

size of 6 nanometers. This algorithm captures the features of

poly-crystalline materials with correct grain boundary structure, size,

and other topological characteristics. We are currently carrying out

large scale molecular dynamics simulation and finite element modeling

to investigate thermodynamic, transport, magnetic and mechanical properties of

nanocrystalline materials."

Multiscale Simulation of Deformation and Fracture in Amorphous Materials

" On the left is the fractography of an amorphous metal

undergoing deformation and fracture. The radiating lines from the semi-circular

notch are shear bands. We are currently carrying out multiscale

simulations, atomistic, mesoscopic and continuum, to try to understand how

and why the deformation occurs in amorphous solids, which do not contain

any extended defects such as dislocations as in crystalline materials.

"

" On the left is the fractography of an amorphous metal

undergoing deformation and fracture. The radiating lines from the semi-circular

notch are shear bands. We are currently carrying out multiscale

simulations, atomistic, mesoscopic and continuum, to try to understand how

and why the deformation occurs in amorphous solids, which do not contain

any extended defects such as dislocations as in crystalline materials.

"

Mechanics on Mesoscales-Effects of Size and Interfaces

"

On the left is the snapshot of a crack during its initial growth. The white areas

are deformed regions. To capature the deformation process which is usually

on the mesoscopic scales and strongly dependent of microstructures, we are

developing a new approach using phase field model. Our goal is to incorporate

various microstructures into the mechanics and capture the

characteristics, such as branching, shear banding, dislocation and grain

boundary interaction, and deformation in composites, during deformation and

fracture.

"

"

On the left is the snapshot of a crack during its initial growth. The white areas

are deformed regions. To capature the deformation process which is usually

on the mesoscopic scales and strongly dependent of microstructures, we are

developing a new approach using phase field model. Our goal is to incorporate

various microstructures into the mechanics and capture the

characteristics, such as branching, shear banding, dislocation and grain

boundary interaction, and deformation in composites, during deformation and

fracture.

"

Phase Separation and Pattern Formation in Multicomponent

Systems

" On the left is the snapshot of two phases, the black

and the grey region, separated from a homogeneous phase of Ising spins using

Monte Carlo method. The

unique feature

is the underlying structure, which is a Sierpinski carpet without translational

symmetry. We are interested in how the topology of the underlying structure,

and composition of multicomponent systems affect the kinetics and thermodynamics

of phase separation."

" On the left is the snapshot of two phases, the black

and the grey region, separated from a homogeneous phase of Ising spins using

Monte Carlo method. The

unique feature

is the underlying structure, which is a Sierpinski carpet without translational

symmetry. We are interested in how the topology of the underlying structure,

and composition of multicomponent systems affect the kinetics and thermodynamics

of phase separation."

Glass Transition and Non-Equilibrium Thermodynamics

" On the left is the snapshot of a liquid-like cluster

in a glass-forming liquid which we found in the simulations using molecular dynamics method. This

ramified structure is observed at temperatures close to the glass transition.

The inhomogeneous and increasingly long-lived "patches" or "islands" in a

supposedly homogeneous liquid is intriguing - is undercooled (metastable) liquid different

from the liquid in equilibrium?

We are currently investigating how the clusters, like the one shown on the left,

contribute to the glass transition and how they affect dynamic and transport properties of glass-forming liquids."

" On the left is the snapshot of a liquid-like cluster

in a glass-forming liquid which we found in the simulations using molecular dynamics method. This

ramified structure is observed at temperatures close to the glass transition.

The inhomogeneous and increasingly long-lived "patches" or "islands" in a

supposedly homogeneous liquid is intriguing - is undercooled (metastable) liquid different

from the liquid in equilibrium?

We are currently investigating how the clusters, like the one shown on the left,

contribute to the glass transition and how they affect dynamic and transport properties of glass-forming liquids."

Electromigration and Damages in Polycrystalline Cu and Al Metals

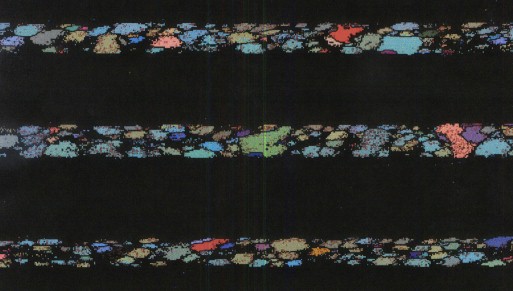

" On the left is the orientation map of polycrystalline

Cu wires used as interconnecting lines in most microelectronic devices

(courtesy of K. Rodbell, IBM T. J. Watson Research Center). The large

electrical current, ~ million Am per square centimeter, passing through these

wires, causes metal atoms to migrate. As a result, voids and extrusions form

in the thin wires and films, causing device failure. As device miniaturization

requires smaller and smaller cross-sections, the electromigration induced failure becomes a serious issue for microelectronic industry. We are currently developing atomistic models and algorithms to model and simulate this phenomenon. In

particular, we are interested in microstructure effect (grain size, orientation,

grain boundary, solute, and second phase) on mass transportation caused by

electromigration in polycrystalline metals.

"

" On the left is the orientation map of polycrystalline

Cu wires used as interconnecting lines in most microelectronic devices

(courtesy of K. Rodbell, IBM T. J. Watson Research Center). The large

electrical current, ~ million Am per square centimeter, passing through these

wires, causes metal atoms to migrate. As a result, voids and extrusions form

in the thin wires and films, causing device failure. As device miniaturization

requires smaller and smaller cross-sections, the electromigration induced failure becomes a serious issue for microelectronic industry. We are currently developing atomistic models and algorithms to model and simulate this phenomenon. In

particular, we are interested in microstructure effect (grain size, orientation,

grain boundary, solute, and second phase) on mass transportation caused by

electromigration in polycrystalline metals.

"

Melting and Crystal-to-Glass Transition

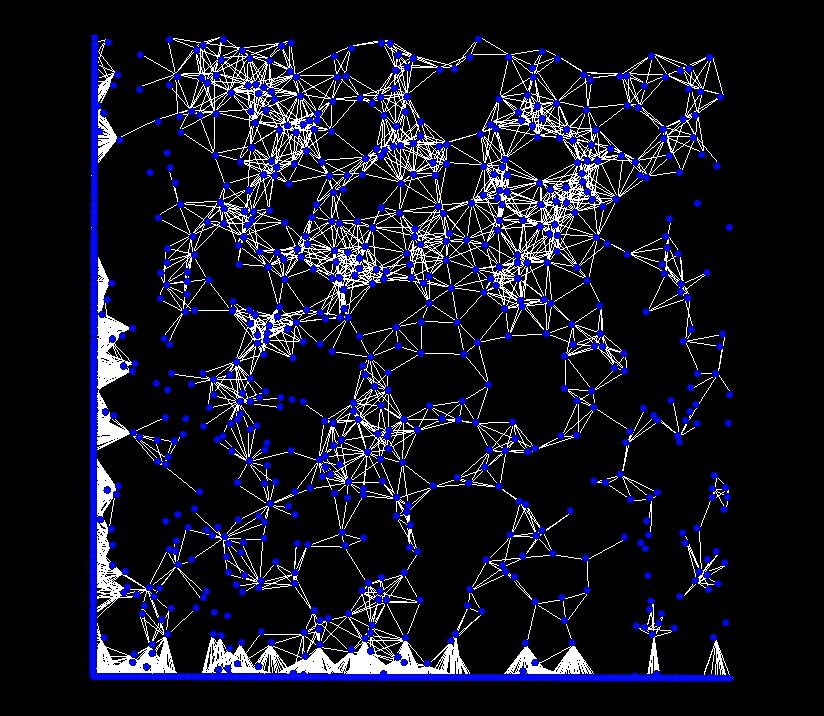

" On the left is the dislocation coupling constant, or

Kosterlitz-Thouless constant, versus disorder from our calculations. As predicted by theory,

melting should occur when the coupling constant decreases to a critical value, 16pi, where

two tightly bonded dislocations start separating. However, when temperature is

high such as in thermal melting, dislocations do not have

to unbind and become singlets; instead they can move together to form even

more complicated

defects such as grain boundaries. Our simulation shows that if the

mobility of dislocations is reduced, the coupling constant indeed reaches

the universal value; as a result, dislocation pairs separate into isolated

singlets, resulting in a continuous melting transition with the formation of the so-called hexatic phase.

We currently extend this work to three dimensions (3D) to search

for mechanisms of melting and crystal-to-glass transition. An

interesting and challenging task is to characterize dislocations in 3D

using atomistic simulation when a large number of dislocations are present in

the system. "

" On the left is the dislocation coupling constant, or

Kosterlitz-Thouless constant, versus disorder from our calculations. As predicted by theory,

melting should occur when the coupling constant decreases to a critical value, 16pi, where

two tightly bonded dislocations start separating. However, when temperature is

high such as in thermal melting, dislocations do not have

to unbind and become singlets; instead they can move together to form even

more complicated

defects such as grain boundaries. Our simulation shows that if the

mobility of dislocations is reduced, the coupling constant indeed reaches

the universal value; as a result, dislocation pairs separate into isolated

singlets, resulting in a continuous melting transition with the formation of the so-called hexatic phase.

We currently extend this work to three dimensions (3D) to search

for mechanisms of melting and crystal-to-glass transition. An

interesting and challenging task is to characterize dislocations in 3D

using atomistic simulation when a large number of dislocations are present in

the system. "

Algorithm and Methodology Development

"

In order to simulate and model physical properties and processes in

highly disordered systems and non-equilibrium processes, unavoidably we need to

develop various new algorithms and simulation methods. (Most of the simulation

algorithms available now are for equilibrium systems.) The following are some of

the highlights in our algorithm development:

(1) We developed a general

algorithm that can reproduce subtle microstructural properties of

nano- and poly-crystalline materials; (2) We found a new way to quench

hard sphere liquids; (3) We developed an

algorithm to calculate cluster lifetime for nucleation and glass

transitions; (4) We developed a new method to compute free volumes in disordered systems.

"

"

In order to simulate and model physical properties and processes in

highly disordered systems and non-equilibrium processes, unavoidably we need to

develop various new algorithms and simulation methods. (Most of the simulation

algorithms available now are for equilibrium systems.) The following are some of

the highlights in our algorithm development:

(1) We developed a general

algorithm that can reproduce subtle microstructural properties of

nano- and poly-crystalline materials; (2) We found a new way to quench

hard sphere liquids; (3) We developed an

algorithm to calculate cluster lifetime for nucleation and glass

transitions; (4) We developed a new method to compute free volumes in disordered systems.

"

|  |